Building Dreams, Tube by Tube: The Hatz CB-1 Fuselage Takes Shape

- Redazione

- Jul 4, 2025

- 2 min read

Updated: Jul 6, 2025

Building an aircraft isn’t just about technique — it’s a story of passion, collaboration, and trust.

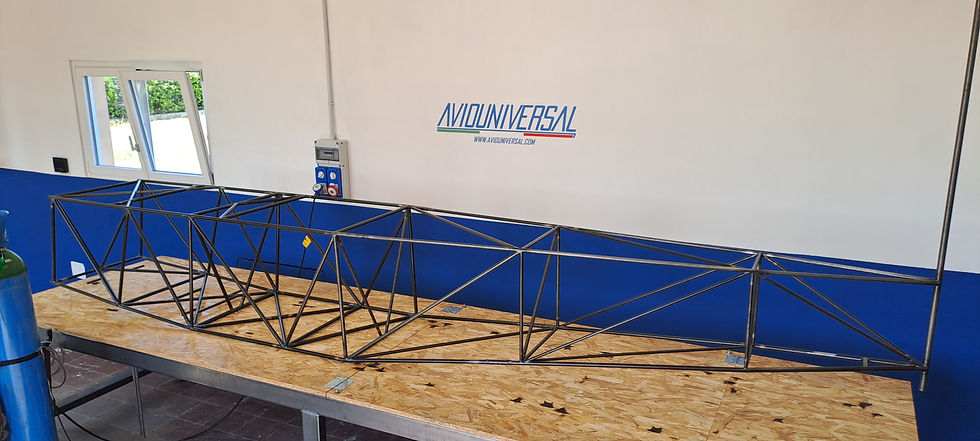

And that’s exactly the spirit behind the construction of this welded steel tube fuselage for the Hatz CB-1, recently completed for a customer who chose to personally take on the challenge of amateur aircraft building.

From Drawing to Reality

When he first contacted us, he had already begun building the wooden wings with great care.

But for the fuselage, he reached out for support: working with 4130 steel tubing requires precision—in both cutting and welding—so we were happy to lend a hand.

We started with the original Hatz CB-1 plans, recreating the entire fuselage structure in a 3D CAD environment, tube by tube.

This approach allowed us to verify geometries, identify potential issues, and, most importantly, prepare CNC-ready tube cutting files, drastically reducing tolerances during assembly.

Once the tubes were precisely cut and prepared, we moved on to assembly: first the side frames, then the cross members, the reinforcements, and finally the closure of the structure. Every joint was treated with the care it deserved—surface prep, tacking, geometric verification, and finally, full welding.

We also followed a dedicated welding sequence designed to minimize distortion and shrinkage.

When working with lightweight structures and tight 3D constraints, every detail matters.

Visible Precision

Once the work was completed, it was time to check the overall result.

Although the original plans didn’t call for tight dimensional tolerances, we adopted high internal standards: all key fuselage stations were found to be aligned within one-tenth of a degree, as verified with a digital level.

That kind of precision speaks to the care and control we put into every phase, from the first tube to the final weld.

Our Philosophy: Supporting Builders

To us, delivering a fuselage isn’t just about “making a part.” It’s about being part of a journey—supporting those who have chosen to build their own aircraft and are looking for a partner to walk the path with them.

With this customer, our collaboration doesn’t end here. We’ll also be assisting during the final assembly phases: helping with wing attachment welding, triangulation, and other critical structural elements. Having someone at your side during the most delicate moments can make a real difference.

Planning to Build Your Own Aircraft?

We’re here to help. Whether you need individual components or a fully welded structure, we can support you through every stage of the project.

And if you’re starting from scratch, we can also assist with design, stress analysis, and structural optimization, to ensure your project is solid, lightweight, and safe.

📩 Reach out for more information or to request a consultation. We’d love to talk airplanes with you.

Comments